NATC can help reduce the development time of a vehicle and still provide real-world testing through an approach called “accelerated life testing.” Drawing on experience in duty cycle development, durability testing, and road profiling, NATC developed and derived a mathematical accelerated life cycle testing approach for a U.S. Air Force nuclear transport vehicle in 1992. Since that time, we have validated this approach through application to numerous commercial and military vehicles.

Each accelerated test design is tailored to the vehicle’s anticipated service environment. Representative road-induced dynamic load conditions are then produced at acceleration factors anywhere from 3:1 to 100:1, depending upon the service environment. A 100:1 acceleration factor means that every mile in NATC’s accelerated test environment equates to the same level of dynamic input (fatigue inducing loads) as 100 miles in the real-world service environment. Our analysis of a vehicle duty cycle, in accelerated test mode, is based on accurate measurements of the road roughness conditions, vehicle speeds, environmental conditions, vehicle payloads, operator driving styles, and other variables.

We utilize direct and remote sensing measurements from the user environment and compare those results with contact and non-contact measurement of terrain roughness, slope, moisture content, vegetation, roughness, and other parameters to correlate with the test environment. Vehicle speeds and other duty cycle parameters complete the analysis. Based on the intended user, other parameters such as fuel quality, tire pressure, trailer type, etc. have to be integrated into the test scenario.

After the duty cycle requirements have been defined, the terrain roughness and associated mobility requirement data are used to design an accelerated life cycle test to evaluate the performance of the test vehicle within the requirements of the duty cycle but in a manner that reduces the distance and time required to accumulate the same level of damaging energy to the vehicle or component. Using the terrain and test course profiles, combined with specific test controls (speed, gear position, steering maneuvers, component cycling, payload cycling, cumulative repetitive events such as braking, railroad crossing, pothole impact, etc.), it is possible to develop an accelerated test that focuses on the specific component, validating that component, while eliminating excess or non-interest events.

The terrain profile and user analysis allows test scenarios to be established quickly without extensive vehicle instrumentation or operation over extended miles or cycles to establish a baseline. Additional advantages of this methodology include:

- Comparisons of terrain roughness for world-wide environments to the test environment can be completed in a vehicle-independent format – identifying the range of conditions in which the vehicle must operate.

- The specific damaging energy or events to the vehicle system or component of interest can be identified accurately. The test scenario is then developed and the data utilized to validate the system or the corrective action to the vehicle and for the impact on overall life cycle cost to be predicted in support of longer term operational and logistics decisions.

The user terrain and associated test course roughness and condition data, typically referred to as profile data, are maintained at NATC and updated based on commercial and DoD related efforts worldwide.

Vehicle speed and road roughness are inseparable terms for defining vehicle inputs, so an analysis of road roughness must also include vehicle speed. For example, 1- to 100-foot wavelengths on a smooth pavement traveled at 68 MPH (100 fps) represents vehicle inputs between 1 and 100 Hz. Those same wavelengths on a rough trail traveled at 27 MPH (40 fps) represent vehicle inputs between 0.4 and 40 Hz. A test design must consider both road roughness and vehicle speed.

Correlation of test results to field use results is best when the types of roughness, soil conditions, grades, etc. match between the test and user environments. NATC combines these loads with environmental loads to more accurately simulate a system’s service life. Another critical control parameter is that the roughest test course used to accelerate the test is not rougher than the roughest terrain in the user environment. This helps to ensure that, while the frequency of the more severe conditions is provided during an accelerated test, the severity of the events does not exceed the operational requirements thereby reducing the potential for an over test situation. Therefore, the “ideal” objective of any accelerated test design is to match the energy between the user and test environments in terms of vertical, lateral, and longitudinal inputs (load and frequency) and to do so without violating the linearity or transfer function relationships of the vehicle.

NATC also combines environmental loads with the road-induced dynamic loads. The effects of corrosion, temperature, humidity, rain, and solar radiation can be combined with the accelerated durability test cycle. The reason for combining environmental tests with the durability is that almost all service environments have some degree of interaction or synergistic effects between dynamic loads and environmental loads.

Overall, accelerated life testing provides an avenue for vehicle and component manufacturers to complete durability and mileage accumulation testing in an expedited manner in order to determine what components on a vehicle system may fail, and when, to support life cycle cost predictions, warranty claim analysis, and production verification for prototype systems. NATC understands and is knowledgeable about vehicle development and real world testing and has the facilities and experience to duplicate service life failures in a short time.

Contact us today to discuss how NATC can assist you.

Test capabilities include measurement of vehicle operating conditions such as:

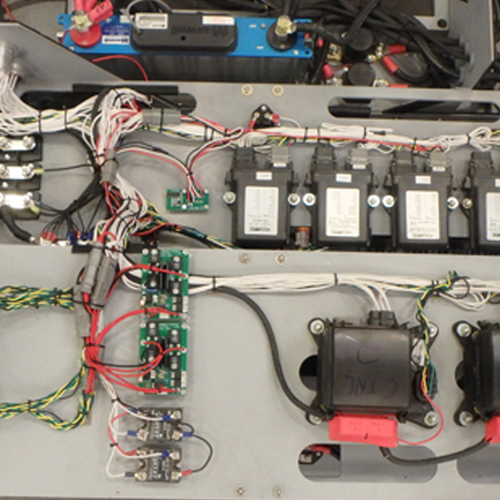

Test capabilities include measurement of vehicle operating conditions such as: To measure fuel consumption, NATC has developed a robust on-board fuel consumption measurement system (OFCMS) that is ruggedized for use in severe duty environments from on-highway to off-road and cross-country conditions. Our systems are designed to function in these non-laboratory conditions using an integrated, positive pressure pump, a built-in deaerator, and large fuel filters to keep clean, single-phase flow. Our system can provide continuous measurement of fuel consumption rates on vehicles using petroleum-based fuels, from small passenger vehicles to large commercial and military vehicles. The OFCMS has been validated and verified to a cumulative error of within 2% in these severe conditions for repeatability and precision of the instantaneous measurement by comparing the cumulative fuel through the meter to fuel consumption measured using a gravimetric method.

To measure fuel consumption, NATC has developed a robust on-board fuel consumption measurement system (OFCMS) that is ruggedized for use in severe duty environments from on-highway to off-road and cross-country conditions. Our systems are designed to function in these non-laboratory conditions using an integrated, positive pressure pump, a built-in deaerator, and large fuel filters to keep clean, single-phase flow. Our system can provide continuous measurement of fuel consumption rates on vehicles using petroleum-based fuels, from small passenger vehicles to large commercial and military vehicles. The OFCMS has been validated and verified to a cumulative error of within 2% in these severe conditions for repeatability and precision of the instantaneous measurement by comparing the cumulative fuel through the meter to fuel consumption measured using a gravimetric method. Measuring on-board fuel consumption has a number of advantages over solely measuring aggregate fuel used over a test run. Individual road segments can be “picked out” of a test run allowing fuel consumption data to be processed for specific conditions, for instance on a 5% grade, or other surface conditions that influence motion resistance, transmission shift points, or other operational parameter. These data can then be used to inform shift schedules, determine efficient speeds for different conditions, and quickly evaluate the advantages and disadvantages of vehicle system or operational changes, etc.

Measuring on-board fuel consumption has a number of advantages over solely measuring aggregate fuel used over a test run. Individual road segments can be “picked out” of a test run allowing fuel consumption data to be processed for specific conditions, for instance on a 5% grade, or other surface conditions that influence motion resistance, transmission shift points, or other operational parameter. These data can then be used to inform shift schedules, determine efficient speeds for different conditions, and quickly evaluate the advantages and disadvantages of vehicle system or operational changes, etc.

NATC conducts brake tests on vehicles ranging from motorcycles to class 8 trucks, with the objective of these tests ranging from developmental testing to compliance testing for government agencies such as NHTSA. We perform brake tests to FMVSS, EC/ECE, ISO, SAE, ASTM, California Title 21, or other specifications as defined by our customers. We also offer specific, customized, brake tests for vehicle development, accident reconstruction/investigation, corrosion, and other customer needs.

NATC conducts brake tests on vehicles ranging from motorcycles to class 8 trucks, with the objective of these tests ranging from developmental testing to compliance testing for government agencies such as NHTSA. We perform brake tests to FMVSS, EC/ECE, ISO, SAE, ASTM, California Title 21, or other specifications as defined by our customers. We also offer specific, customized, brake tests for vehicle development, accident reconstruction/investigation, corrosion, and other customer needs. Designed and built in-house by NATC engineering and fabrication personnel, the tilt table augments NATC’s vehicle dynamics testing capabilities. These capabilities include, but are not limited to, handling, roll stability quantification, end limit performance, side slope operation, fork lift capability, active suspension development, and a multitude of

Designed and built in-house by NATC engineering and fabrication personnel, the tilt table augments NATC’s vehicle dynamics testing capabilities. These capabilities include, but are not limited to, handling, roll stability quantification, end limit performance, side slope operation, fork lift capability, active suspension development, and a multitude of

Corrosion is one of the more critical and influential variables that contributes to a vehicle’s overall life cycle cost and durability, and we understand the detrimental effects it may have on a vehicle system. When performing durability corrosion testing, we evaluate a test article’s duty cycle and focus on the elements that have the greatest effect on corrosion characteristics. To evaluate those effects, we conduct many corrosion/durability evaluations where discrete over-the-road type corrosion elements are introduced to the test article within its mission profile mileage accumulation. We ensure repeatable results by using standardized coupons during testing to monitor corrosion rate and mass loss.

Corrosion is one of the more critical and influential variables that contributes to a vehicle’s overall life cycle cost and durability, and we understand the detrimental effects it may have on a vehicle system. When performing durability corrosion testing, we evaluate a test article’s duty cycle and focus on the elements that have the greatest effect on corrosion characteristics. To evaluate those effects, we conduct many corrosion/durability evaluations where discrete over-the-road type corrosion elements are introduced to the test article within its mission profile mileage accumulation. We ensure repeatable results by using standardized coupons during testing to monitor corrosion rate and mass loss.

We achieve dynamic loads by traversing numerous

We achieve dynamic loads by traversing numerous

Obstacles and Grades

Obstacles and Grades