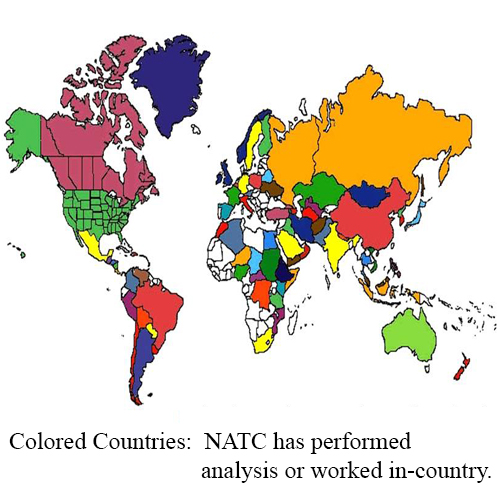

NATC engineers consult with our automotive customers from around the world on a comprehensive range of programs and multi-faceted issues related to vehicle design and development, procedures and standards, and specialized tests.

Vehicle Development

Working with our customers, we account for requirements of vehicle usage profiles and manufacturing capabilities to help optimize designs, development, and manufacturing costs. We identify strengths and weaknesses of the customer developed vehicle solution using applicable references, standards, and historical platforms. And, we help customers create verification and validation test plans to negate risk and ensure a market ready product release.

Our engineers are technical experts across a broad range of the transportation industry including passenger and commercial vehicles, off-road recreational vehicles, as well as agricultural, vocational, and military vehicles. Because we have the engineering expertise, the modeling and simulation tools, and the physical test and validation facilities in one location, we offer a complete solution to our customers’ needs.

Our engineers are technical experts across a broad range of the transportation industry including passenger and commercial vehicles, off-road recreational vehicles, as well as agricultural, vocational, and military vehicles. Because we have the engineering expertise, the modeling and simulation tools, and the physical test and validation facilities in one location, we offer a complete solution to our customers’ needs.

Maintenance/Operating Procedures

NATC has significant experience in initial development, review, change, temporary change, and revision of maintenance and operating procedures used by military and industry clients. Collaborating with our clients, we define the level of skill set associated with procedures and the level of assumed knowledge for the target audience. With certified master mechanics and experienced former military maintainers on staff, we develop effective, affordable maintenance and operating procedures, and deliver them in a format that can conform to industry or DOD standards.

Standards

NATC assists regulatory agencies, fleet managers, and vehicle purchasers to develop vehicle requirements and standards by using our extensive knowledge of on- and off-road vehicle operations and lessons learned from historical requirements documents. We assist our customers with determining the system capabilities that are most critical and with resolving conflicting requirements. We have the technical background and vehicle development and testing background to take notional vehicle descriptions and transfer them into concrete, objective, and testable requirements statements. Further, our engineers are active voting members of multiple committees in standards development organizations such as SAE, ISO, TRB, ATA, etc. tasked with maintaining and developing new ground vehicle standards.

Specialized Tests

We strive to meet all of our customers’ testing and diagnostic needs. Whether setting up tests for a root cause failure analysis, or testing a proof of concept, we excel at non-standardized and specialized testing. We have the resources and experience necessary to create and set up any test a customer may need.

Resources include, but are not limited to:

- Dedicated instrumentation department focused on capturing relevant data

- Dedicated electronics and controls department with the ability to custom make precision controlled testing fixtures and controllers

- Engineering department to design and develop tests

- 3-D CAD and simulation capabilities including FEA of components and systems, fatigue and life cycle estimates, and full dynamic simulation models

- High-speed video and 3-D video tracking software

- Aerial photography using unmanned aerial systems

- Fully outfitted fabrication and machine shops with certified welders

Experience and knowledge include, but are not limited to:

- Development of consistent vehicle compartment fires to test vehicle mounted fire suppression systems

- Development of device to consistently flip vehicles to test rollover protection systems

- Testing of night vision and nighttime driving systems on miles of privately owned courses

- Development of fixtures to allow structural testing while minimally affecting the load path

Custom Automotive Engineering Consulting Services

Our engineers are technical experts across a broad range of the transportation industry including passenger and commercial vehicles, off-road recreational vehicles, as well as agricultural, vocational, and military vehicles. Because we have the engineering expertise, the modeling and simulation tools, and the physical test and validation facilities in one location, we offer a complete solution to our customers’ needs.

Our engineers are technical experts across a broad range of the transportation industry including passenger and commercial vehicles, off-road recreational vehicles, as well as agricultural, vocational, and military vehicles. Because we have the engineering expertise, the modeling and simulation tools, and the physical test and validation facilities in one location, we offer a complete solution to our customers’ needs.

Private passenger vehicles

Private passenger vehicles